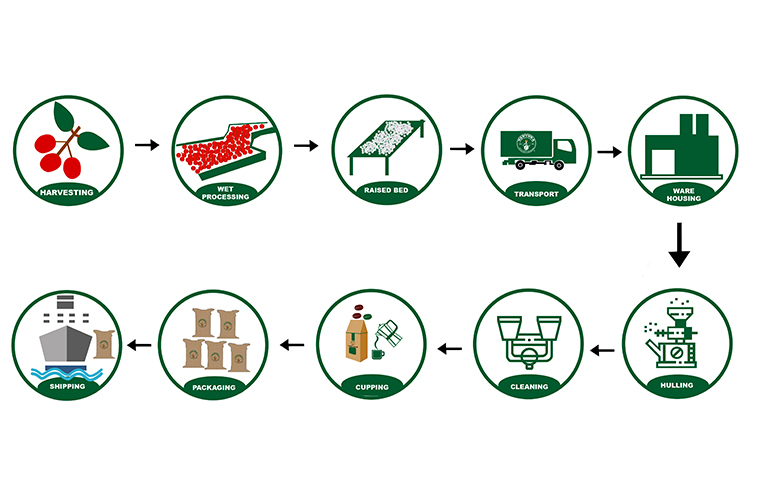

The Washed coffee processing method includes the following steps at the various washing stations:

1. Red cherries are collected from farmers, and purchases from farmers monitored by responsible person

2. Then pulped to separate the skin and during which light and unripe coffees are separated (through floater)

3. The pulped coffee then put into fermentation tank with clean spring water. It has to wait from 36-72 hours during which water has to be changed 3 times. When the mucilage is removed, the fermented coffee is released to the canals where the coffee is washed and floaters are separated again

4. Then the coffee is put into soaking tank for 8-16 hours to increase quality

5. After that, it is moved into parchment drying table for one day to let the water evaporate

6. Then moved into beds with wooden posts for drying

7. Workers continuously stir the coffee for uniform drying and to avoid moisture concentration

8. Based on desirable moisture level, the parchment is dried for 9-12 days

9. Transported to Addis Ababa where we have a hulling machine to separate the impurities and defects before bagged for export